Exhaust gas treatment

Tags:

Belongs to Category:

Exhaust gas treatment

Product Description

Overview

Industrial production processes release a wide variety of VOCs with vastly different properties. In most cases, production process exhaust gases contain multiple types of pollutants simultaneously. The operating conditions of process exhaust gases discharged from different production processes are diverse, and the operating conditions of exhaust gases discharged from different processes within the same industry or even different processes within the same industry also vary greatly. Therefore, it is crucial to select and improve appropriate VOCs exhaust gas treatment processes according to the specific process.

Various VOCs treatment technologies have been developed, and the selection in practical applications needs to be based on the nature and emission characteristics of the pollutants.

Waste gas treatment methods mainly include: physical methods, combustion methods, chemical oxidation methods, absorption methods, biological methods, etc., while "plasma methods" have opened up a new path for odor treatment.

Waste Gas Treatment Processes

For the treatment of a large number of organic compounds present in industrial waste gases, commonly used methods such as activated carbon, activated carbon fiber, pure silicon molecular sieves, and catalytic combustion, while having some effect, not only consume a large amount of adsorbent materials or fuel, but also have problems such as backward technology, high cost, and serious secondary pollution. This is especially true for high-volume, low-concentration organic waste gases, where many problems remain unsolved. In fact, the adoption of these technical solutions often causes great difficulties for government environmental protection departments' supervision and the operation of enterprises that generate and treat pollution.

Adsorption-Desorption Treatment

Activated carbon has a good adsorption effect on certain specific VOC factors and can be desorbed and regenerated. Although there are problems such as high actual operating costs, troublesome secondary treatment, and difficult real-time monitoring of the effect, it still occupies an important position in the traditional treatment process of organic waste gases.

Catalytic Combustion

When the VOC concentration in waste gas is generally below 2000 mg/m3 and unstable, combustion requires the supplementary consumption of a large amount of energy. This not only increases operating costs but also deviates significantly from the environmental governance goal of energy saving and emission reduction. The use of "catalytic combustion" will greatly increase the emission of CO2 into the atmosphere, and some waste gas factors (such as phenyl chloroformate, 1,3-dichloropropanone dust, etc.) will produce highly toxic dioxins (trace amounts exceed the national atmospheric emission standards, and control is very strict) and other secondary pollutants after combustion. Therefore, catalytic combustion is not suitable for the treatment of certain organic waste gases. In fact, the use of catalytic combustion will also greatly increase the amount of pipeline engineering.

Low-Temperature Plasma Treatment

The plasma generates particles rich in high chemical activity, such as electrons, ions, free radicals, and excited molecules. The pollutants in the waste gas react with these highly energetic active groups and are ultimately converted into substances such as CO2 and H2O, thereby achieving the purpose of purifying the waste gas. Wide range of applications, high purification efficiency, especially suitable for multi-component odorous gases that are difficult to treat by other methods, such as the chemical and pharmaceutical industries. Small footprint, high electron energy, can interact with almost all odorous gas molecules; low operating costs; fast reaction, quick shutdown, and on-demand operation. The disadvantage is that the one-time investment is slightly higher.

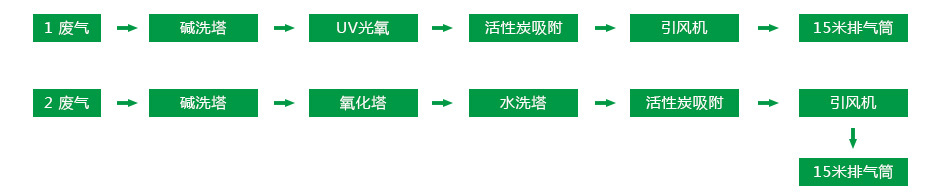

Typical Process Flow

Leave a Message

Fill in your phone number and E-mail information, and we will contact you within one working day to solve your problems as soon as possible.

-- Recommended --

Shijiazhuang Tianwang Environmental Protection Technology Co., Ltd.

Shijiazhuang Tianwang Environmental Protection Technology Co., Ltd. is a high-tech enterprise specializing in the research and development, manufacturing and sales of water treatment equipment.

Contact Information

Production address: No. 9, Fengchan Road, Economic and Technological Development Zone, Shijiazhuang City

Office Address: 25th Floor, Block C, No. 310 Changjiang Avenue, Shijiazhuang High-tech Development Zone

Contact Number:

0311-89272359 0311-68039237

Enterprise Email:

twhbkj@163.com

Website: en.sjztwhb.com