12-25

Attend the 2024 Spring Qingdao Pharmacy Exhibition

01-12

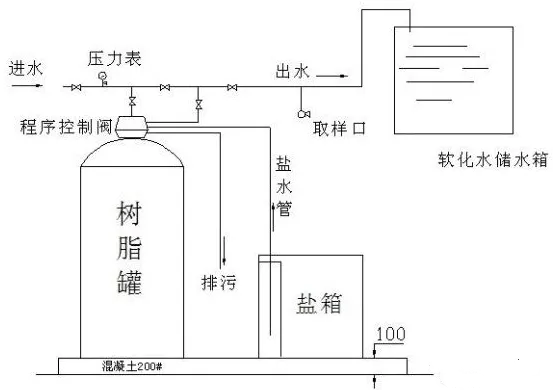

Key points for softening water equipment installation

01-07

Polishing resin function and filling method of ultrapure water equipment

12-22

12-06

What is severe fouling of reverse osmosis membranes?

11-30

How to deal with reverse osmosis membrane blockage

11-19

What are some ways that membranes can be arranged?

11-15

Principle and operation method of industrial EDI ultrapure water equipment

11-04

What is oxidation-reduction potential (ORP)?

11-01

Summary of 31 pure water process problems

Shijiazhuang Tianwang Environmental Protection Technology Co., Ltd.

Shijiazhuang Tianwang Environmental Protection Technology Co., Ltd. is a high-tech enterprise specializing in the research and development, manufacturing and sales of water treatment equipment.

Contact Information

Production address: No. 9, Fengchan Road, Economic and Technological Development Zone, Shijiazhuang City

Office Address: 25th Floor, Block C, No. 310 Changjiang Avenue, Shijiazhuang High-tech Development Zone

Contact Number:

0311-89272359 0311-68039237

Enterprise Email:

twhbkj@163.com

Website: en.sjztwhb.com