06-30

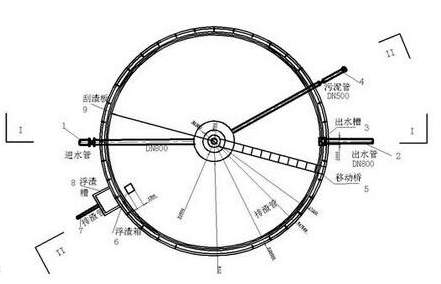

Reasons for exceeding the suspended solids standard in the secondary sedimentation tank effluent

06-16

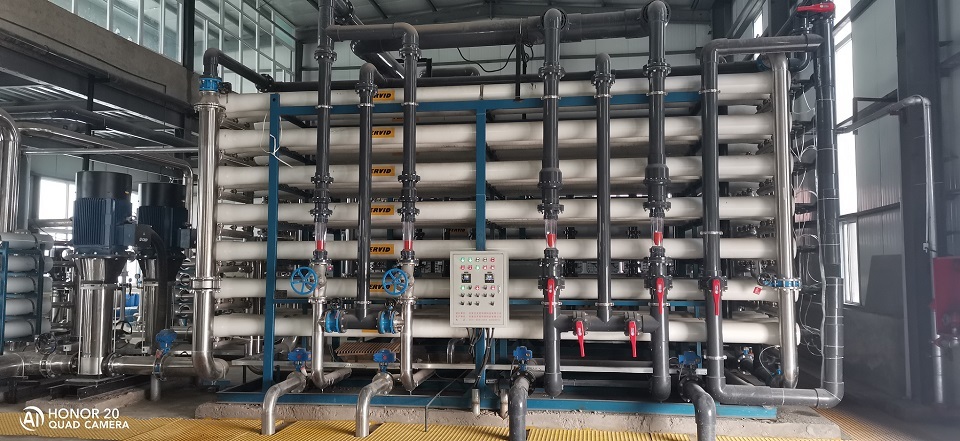

How do Hebei reverse osmosis equipment manufacturers handle equipment malfunctions?

06-10

Items to confirm before operating a small reverse osmosis device

05-29

Hebei reverse osmosis equipment manufacturers teach you how to identify water treatment agents

05-29

05-29

Characteristics and principles of small reverse osmosis equipment

05-25

What are the differences between small and large reverse osmosis equipment?

05-21

How to fix common problems with industrial reverse osmosis equipment?

05-19

Detailed Explanation of Industrial Reverse Osmosis Equipment

05-15

Frequently Asked Questions about Reverse Osmosis Equipment (Part 2)

Shijiazhuang Tianwang Environmental Protection Technology Co., Ltd.

Shijiazhuang Tianwang Environmental Protection Technology Co., Ltd. is a high-tech enterprise specializing in the research and development, manufacturing and sales of water treatment equipment.

Contact Information

Production address: No. 9, Fengchan Road, Economic and Technological Development Zone, Shijiazhuang City

Office Address: 25th Floor, Block C, No. 310 Changjiang Avenue, Shijiazhuang High-tech Development Zone

Contact Number:

0311-89272359 0311-68039237

Enterprise Email:

twhbkj@163.com

Website: en.sjztwhb.com