Quartz sand filter

Tags:

Belongs to Category:

Quartz sand filter

Product Description

Overview

Natural water contains various impurities. These can be broadly classified into three categories: suspended matter, colloidal matter, and dissolved matter. With the gradual improvement of people's living standards, various industries have increasingly stringent requirements for water quality. Therefore, pre-treatment of water is essential. Practice has proven that the quality of water pre-treatment has a significant impact on the long-term stable operation of subsequent water treatment equipment.

Mechanical filters are mainly used for turbidity removal in water supply and drainage treatment, pre-treatment of softened water and pure water, and removal of suspended solids, mechanical impurities, and some colloidal substances from raw water. The influent turbidity should be less than 20 degrees, and the effluent turbidity can reach below 3 degrees. Our factory produces mechanical filters in various materials, including stainless steel and epoxy-lined steel. When stainless steel is used, it can be used for the treatment of food and pharmaceutical water.

Structural Form

The mechanical filter consists of a shell, end caps, upper and lower water distribution devices, sealing rings, operating valves, pressure gauges, etc. According to different water quality requirements, single-layer, double-layer, or multi-layer filter media can be used to meet water requirements.

Uses

Mechanical filters are widely used in the pretreatment of industrial and domestic water, as well as in water supply and drainage treatment in chemical, dyeing, pesticide, coking, fertilizer, pharmaceutical, solvent, electroplating, environmental protection, and other industrial sectors, and in the deep purification treatment of industrial wastewater.

Classification of Mechanical Filters

Mechanical filters are usually divided into gravity type and pressure type according to their pressure, with the pressure type being more commonly used. According to their specifications, they are further divided into small and large types.

(1) Small mechanical filters are generally made of two materials: one is a high-quality carbon steel container with a working pressure ≤0.6Mpa; the other is stainless steel with a working pressure ≤0.4Mpa. Backwashing only uses pressure water, generally without air scrubbing, and the filter media can be single-layer, double-layer, or multi-layer according to the raw water quality.

(2) Large mechanical filters: There are two types: single-flow and double-flow, with a series ranging from 750 to 3000. The water treatment capacity ranges from 4m³/h to 100m³/h, and the filter layer can be single-layer or double-layer.

Performance of Quartz Sand Filter Media

Quartz sand has a density of (2.5-2.7), which is greater than that of smokeless coal. It is used in combination with smokeless coal in the second layer of double-layer or multi-layer filter media devices and is currently a widely used ideal filter media in water treatment. Quartz sand filter media is made by crushing, screening, and purifying refined quartz sandstone. It is a pure white, glossy crystal. It has the characteristics of high mechanical strength, good chemical stability, and long service life required for filter media.

(1) Physical and Chemical Properties of Quartz Sand

Physical and Chemical Properties Table of Quartz Sand

|

Item |

Index |

Item |

Index |

|

Mohs Hardness |

7.5 degrees |

Abrasion Rate |

0.003% |

|

Melting Point |

1480℃ |

Crushing Rate |

0.035% |

|

Density |

2.66g/cm³ |

Hydrochloric Acid Soluble Rate |

0.2% |

|

Bulk Density |

1.75g/cm³ |

SiO2 |

99.8% |

|

Porosity |

43% |

|

|

Note: The appearance is a white glossy crystal, with hard and uniform particles, and no other impurities.

(2) General Specifications of Quartz Sand Filter Media

General Specifications Table of Quartz Sand Filter Media

|

Particle Size Range (mm) |

Particle Size Range (mm) |

|

0.5-1.2 |

1.0-1.8 |

|

0.5-1.5 |

1.0-2.5 |

|

0.6-0.9 |

2.0-4.0 |

|

0.8-1.2 |

4.0-8.0 |

|

0.8-2.0 |

8.0-15.0 |

|

1.0-1.5 |

15-25 |

Note: 1. An error of ±0.2mm is allowed for individual particle sizes;

2. The weight of particles smaller than the lower limit is ≤3%;

3. Allowable weight of particles larger than the upper limit ≤2%;

4. Uniformity coefficient K80 ≤2.0.

► Filter media gradation

1. Single-layer filter media and support layer

700 mm of quartz sand with a particle size of 0.8-2.0 mm. The support layer is shown in the table below (the support layer can use 2-25 mm sand and gravel, layered from fine to coarse according to the actual situation).

Filter media support layer composition

|

Layer (from top to bottom) |

Particle size (mm) |

Thickness (mm) |

|

1 |

2-4 |

100 |

|

2 |

4-8 |

100 |

|

3 |

8-16 |

100 |

|

4 |

16-32 |

100 |

The normal filtration rate of the above filter media is 10-17 m/h. When backwashing, the water temperature is 10℃, the washing intensity is 8-10 L/m²•S, and the washing time is 10-15 minutes.

2. Double-layer filter media

The upper layer is 2-3 mm smokeless coal, and the lower layer is quartz sand with a diameter of 1.0-2.5 mm. The thickness depends on the water pressure, water output, and water quality.

3. Multi-layer filter media

Multi-layer filter media has a larger interception capacity and adaptability than general single and double-layer filter media. The filter contains five layers, from top to bottom:

Smokeless coal d=1-2mm

Quartz sand d=0.5-1-32mm

Garnet d=0.3-0.5mm

Gravel d=10mm

4. The height and particle size depend on the water pressure, water output, and water quality.

The bottom layer uses pebbles as the support layer. The layered filter media has good gradation and specific gravity difference, so as to achieve the best filtration effect. The normal filtration rate is 15 m/h. When the head loss of water passing through the filter layer reaches 0.05-0.1 MPa, backwashing is carried out.

► Specifications, models, and technical parameters of mechanical filters

Specifications and performance of steel mechanical filters

|

Model |

Specifications |

Maximum water output |

Operating temperature |

Filtration area |

Filtration rate |

Filter media layer height |

Maximum outer dimensions |

Net weight |

|

CJQ-30 |

ø300 |

1.05 |

4-50 |

0.07 |

8-15 |

700 |

ø 400 x 1652 |

189 |

|

CJQ-40 |

ø400 |

1.89 |

4-50 |

0.126 |

8-15 |

700 |

ø 550 x 1770 |

242 |

|

CJQ-50 |

ø500 |

2.94 |

4-50 |

0.196 |

8-15 |

1000 |

ø 644 x 2210 |

383 |

|

CJQ-75 |

ø750 |

6.6 |

4-50 |

0.44 |

8-15 |

1000 |

ø 884 x 2385 |

638 |

|

CJQ-100 |

ø1000 |

11.8 |

4-50 |

0.78 |

8-15 |

1200 |

ø1012 x 2297 |

880 |

|

CJQ-150 |

ø 1500 |

26.5 |

4-50 |

1.76 |

8-15 |

1200 |

ø1516 x 3469 |

1506 |

|

CJQ-200 |

ø 2000 |

47.1 |

4-50 |

3.14 |

8-15 |

1200 |

ø2020 x 3610 |

2455 |

|

CJQ-250 |

ø 2500 |

73.6 |

4-50 |

4.90 |

8-15 |

1200 |

ø2524 x 4020 |

4179 |

|

CJQ-300 |

ø 3000 |

105.9 |

4-50 |

7.06 |

8-15 |

1200 |

ø3028 x 4480 |

6355 |

Note: 1. The maximum working pressure is 0.6 MPa, and the test pressure is 0.9 MPa.

2. The internal pebble cushion layer and filter media layer (quartz sand) are handled by the user.

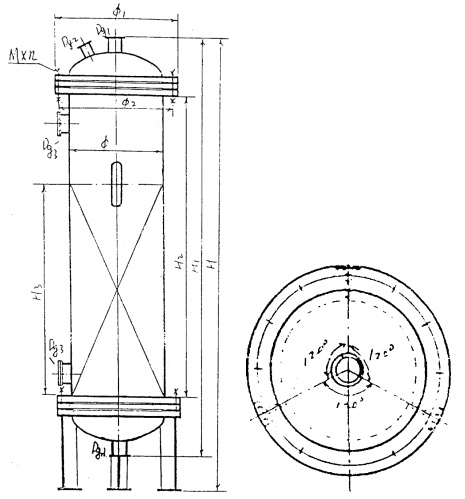

Figure 1 GJQ-30 to GJQ-75

The outer dimensions (mm) of the GJQ-30 to 75 steel mechanical filters are shown in Figure 1.

|

Specifications |

H |

H1 |

H2 |

H3 |

ø1 |

ø2 |

Mn |

Dgl |

Dg2 |

Dg3 |

|

ø300 |

1652 |

1502 |

1100 |

700 |

400 |

368 |

ø12×12 |

25 |

15 |

40 |

|

ø400 |

1770 |

1620 |

1100 |

700 |

550 |

490 |

øl4×16 |

32 |

25 |

40 |

|

ø500 |

2210 |

2060 |

1500 |

1000 |

644 |

590 |

ø16×18 |

40 |

25 |

50 |

|

ø750 |

2385 |

2235 |

1500 |

1000 |

864 |

824 |

ø18×20 |

65 |

32 |

50 |

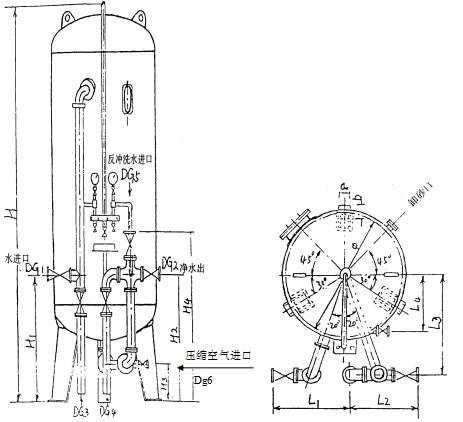

External dimensions (mm) of GJQ-100 to GJQ-300 steel mechanical filters, see Figure 2

|

Specifications |

H |

H1 |

H3 |

H4 |

Ha |

L1 |

L2 |

L3 |

L4 |

Dgl |

Dg2 |

Dg3 |

Dg4 |

Dg5 |

Dg6 |

a |

b |

ø |

|

ø1000 |

2897 |

905 |

905 |

165 |

126l |

629 |

629 |

750 |

470 |

65 |

65 |

80 |

65 |

80 |

40 |

160 |

125 |

990 |

|

ø1500 |

3465 |

1025 |

1025 |

185 |

1426 |

870 |

870 |

1000 |

614 |

80 |

80 |

100 |

80 |

100 |

50 |

180 |

140 |

1450 |

|

ø2000 |

3610 |

1100 |

1100 |

195 |

1481 |

882 |

882 |

1255 |

799 |

100 |

100 |

150 |

100 |

150 |

80 |

250 |

200 |

1800 |

|

ø2500 |

4020 |

1150 |

1150 |

205 |

1661 |

1032 |

1032 |

1500 |

941 |

125 |

125 |

150 |

125 |

150 |

100 |

350 |

300 |

2000 |

|

ø3000 |

4480 |

1200 |

1200 |

220 |

1811 |

1178 |

1178 |

1750 |

1005 |

150 |

150 |

200 |

150 |

200 |

100 |

400 |

300 |

2400 |

Backwash drain Forward wash drain

Figure 2 GJQl00 to GJQ300 mechanical filter

Leave a Message

Fill in your phone number and E-mail information, and we will contact you within one working day to solve your problems as soon as possible.

-- Recommended --

Shijiazhuang Tianwang Environmental Protection Technology Co., Ltd.

Shijiazhuang Tianwang Environmental Protection Technology Co., Ltd. is a high-tech enterprise specializing in the research and development, manufacturing and sales of water treatment equipment.

Contact Information

Production address: No. 9, Fengchan Road, Economic and Technological Development Zone, Shijiazhuang City

Office Address: 25th Floor, Block C, No. 310 Changjiang Avenue, Shijiazhuang High-tech Development Zone

Contact Number:

0311-89272359 0311-68039237

Enterprise Email:

twhbkj@163.com

Website: en.sjztwhb.com