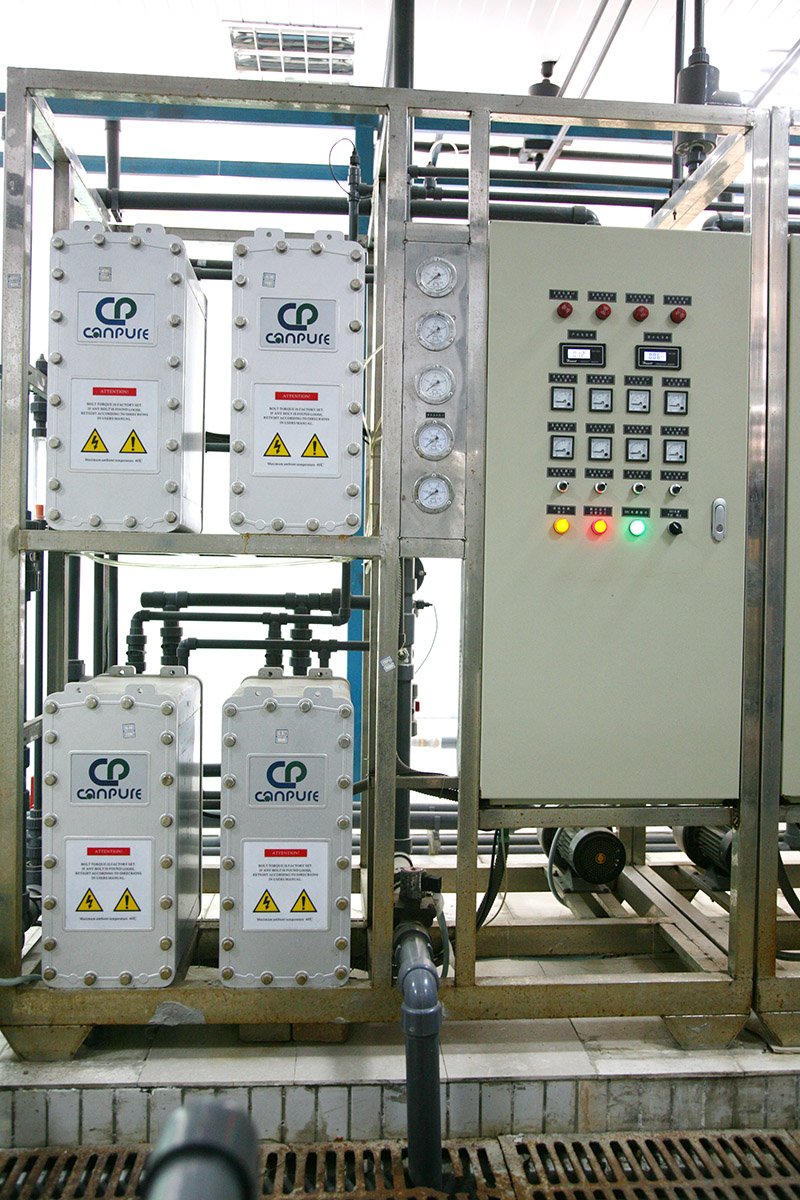

EDI Technology Introduction

EDI (Electrodeionization) is a pure water manufacturing technology that combines ion exchange technology, ion exchange membrane technology and ion electromigration technology. It is a clever combination of electrodialysis and ion exchange technology, using the electrodes at both ends of the high pressure to make the charged ions in water move, and with ion exchange resin and selective resin membrane to accelerate the ion movement removal, so as to achieve the purpose of water purification. Thus, the EDI system here is a pure water manufacturing system.

In the EDI desalination process, ions are removed through the ion exchange membrane under the action of an electric field. At the same time, water molecules produce hydrogen and hydroxide ions under the action of the electric field. These ions continuously regenerate the ion exchange resin in order to keep the ion exchange resin in optimal condition.

EDI ultrapure water equipment ultrapure water manufacturing history process stage 1: pretreatment filter --> cation bed --> negative bed --> mixed bed stage 2: pretreatment filter --> Reverse Osmosis --> Mixed Bed Current Stage: Pretreatment Filter --> Reverse Osmosis --> EDI (without acid-base)

In recent decades, mixed-bed ion exchange technology (D) has been used as the standard process for ultrapure water preparation. Since it requires periodic regeneration and the regeneration process consumes a large amount of chemicals (acid and alkaline) and industrial pure water and causes certain environmental problems, there is a need to develop acid and alkaline-free ultrapure water systems. Because traditional ion exchange is increasingly unable to meet the needs of modern industry and environmental protection, EDI technology, which combines membranes, resins and electrochemical principles, has become a revolution in water treatment technology. The regeneration of ion exchange resins uses electrical energy and no longer requires acid or alkali, thus meeting the environmental requirements of today's world.

Electric deionization (EDI) system is mainly under the action of DC electric field, through the partition of the water dielectric ion directional movement, the use of exchange membrane on the ion selective permeation to purify the water quality of a scientific water treatment technology. Electrodialysis between a pair of electrodes, usually by the anion membrane, cation membrane and spacer (A, B) alternating groups, constituting a concentrated chamber and light chamber (i.e., cations can pass through the cation membrane, anions can pass through the anion membrane). Light chamber water cation to the negative migration through the cation membrane, by the concentration of the chamber in the anion membrane retention; water anion to the positive direction of the migration of the anion membrane, by the concentration of the chamber in the cation membrane retention, so that the number of ions through the light chamber of the water gradually reduced to become fresh water, while the concentration of the chamber of the water, due to the concentration of the chamber of the anion and cation into constantly, the concentration of dielectric ions rising, and become concentrated water, so as to achieve desalination, purification, concentration or refinement of the purpose.

Since the industrialization of EDI membrane stack technology in 1986, thousands of EDI systems have been installed all over the world, and it has been vigorously developed in pharmaceutical, semiconductor, power and surface cleaning industries, as well as widely used in wastewater treatment, beverage and microbiology fields.

EDI equipment is applied after the reverse osmosis system to replace the traditional mixed bed ion exchange technology (MB-DI) to produce stable ultra-pure water.

EDI technology has the following advantages compared with mixed bed ion exchange technology:

①Stable water quality

②Easy to realize fully automatic control

③No downtime due to regeneration

④No chemical regeneration required

⑤Low operating cost

⑥Small plant area

⑦No sewage discharge

EDI working principle:

The EDI module is composed of ion exchange resin sandwiched between anion and cation exchange membranes to form EDI units, and the working principle of EDI is shown in the figure. The EDI module separates a certain number of EDI cells with a grid to form a concentrated water chamber and a fresh water chamber. Anion/anode electrodes are also set at both ends of the unit set. The anions and cations in the water flowing through the fresh water chamber pass through the anion and cation exchange membrane to the concentrated water chamber and are removed in the fresh water chamber under the driving force of direct current. The water passing through the concentrated water chamber takes the ions out of the system and becomes concentrated water. EDI equipment generally uses secondary reverse osmosis (RO) pure water as EDI feed water. RO pure water resistivity is generally 40-2μS/cm (25℃). pure water.

Operation.

(1) The effect of EDI feed water conductivity. At the same operating current, as the conductivity of the raw water increases the EDI removal rate of weak electrolytes decreases and the conductivity of the effluent water also increases. If the raw water conductivity is low then the ion content is also low, and the low concentration of ions makes the electric potential gradient formed on the surface of the resin and membrane in the light chamber is also large, resulting in enhanced dissociation of water, increased limit current, and a higher amount of H+ and OH- produced, making the regeneration of the anion and cation exchange resin filled in the light chamber effective.

(2) The effect of working voltage-current. The working current increases and the quality of produced water keeps getting better. But if the current increases again after increasing to the highest point, due to the amount of H+ and OH- ions generated by water ionization is too much, in addition to the regeneration of resin, a large number of surplus ions act as a carrier ion conductive, and at the same time, due to a large number of carrier ions move in the process of accumulation and blockage, and even counter-diffusion, the result of the water quality decline.

(3) turbidity, pollution index (SDI) of the impact of EDI components produced water channel filled with ion exchange resin, too high turbidity, pollution index will make the channel blockage, resulting in the system differential pressure rises, water production decreases.

(4) the impact of hardness. If the residual hardness of the incoming water in EDI is too high, it will lead to membrane surface scaling in the concentrated water channel, the concentrated water flow decreases, and the resistivity of the produced water decreases; it will affect the quality of produced water, and it will seriously block the concentrated water and extreme water channel of the component, leading to the destruction of the component due to internal heating.

(5) TOC (total organic carbon) impact. If the organic content of the feed water is too high, it will cause organic contamination of the resin and selective permeability membrane, resulting in an increase in system operating voltage and a decrease in the quality of produced water. It is also easy to form organic colloid in the concentrated water channel and block the channel.

(6) The impact of CO2 in the feed water. HCO3- generated by CO2 in the inlet water is a weak electrolyte, easy to penetrate the ion exchange resin layer and cause a decline in water quality.

(7) the impact of total anion content (TEA). High TEA will reduce EDI produced water resistivity, or the need to increase the EDI operating current, and too high operating current will lead to increased system current, the residual chlorine concentration of the polar water increases, which is not conducive to the life of the polar membrane.

In addition, the feed water temperature, pH, SiO2 and oxides also have an impact on EDI system operation.

Inlet water quality control.

(1) the control of the feed water conductivity. Strictly control the conductivity of the pre-treatment process, so that the EDI feed water conductivity less than 40μS/cm, can ensure that the discharge water conductivity qualified and weak electrolyte removal.

(2) Working voltage-current control. When the system works, the appropriate operating voltage - current should be selected. At the same time, because the EDI water purification equipment voltage - current curve on the existence of a limit voltage - current point location, with the inlet water quality, membrane and resin performance and membrane on the structure and other factors [4]. In order to ionize a certain amount of water to produce a sufficient amount of H+ and OH- ions to regenerate a certain amount of ion exchange resin, the voltage - current operating point of the selected EDI water purification equipment must be greater than the limiting voltage-current point.

(3) Control of incoming CO2. The pH can be adjusted by adding alkali before RO to remove CO2 to the maximum extent, and CO2 can also be removed by degassing tower and degassing membrane.

(4) Control of feed water hardness. It can be combined with CO2 removal, softening and alkali addition to RO feed water; when the feed water contains high salinity, it can be combined with desalination to add a level of RO or nanofiltration.

(5) TOC control. Combined with other index requirements, add a level of RO to meet the requirements.

(6) turbidity, pollution index control. Turbidity, pollution index is one of the main indicators of RO system feed water control, qualified RO effluent can generally meet the EDI feed water requirements.

(7) the control of Fe. Operation control EDI feed water Fe less than 0.01mg / L. If the resin has been "poisoning", you can use the acid solution for recovery treatment, the effect is better.

Application range

1、Semiconductor and electronic industry - ultrapure water

2、Biological and pharmaceutical industries - purified water

3、Power plant - boiler feed water

4、Surface coating

5、Consumer and cosmetic industry

6、Replace all kinds of distilled water

7、Other industries that require high purity of water

leave me a message

-- Recommend --

Shijiazhuang Tianwang Environmental Protection Technology Co., Ltd.

Shijiazhuang Tianwang Environmental Protection Technology Co., Ltd. is a high-tech enterprise specializing in the research and development, manufacturing and sales of water treatment equipment.

Contact information

Production address: No. 9, Fengchan Road, Economic and Technological Development Zone, Shijiazhuang City

Office Address: 25th Floor, Block C, No. 310 Changjiang Avenue, Shijiazhuang High-tech Development Zone

Contact number:

Copyright ©2022 Shijiazhuang Tianwang Environmental Protection Technology Co., Ltd. 冀ICP备13019843号-1 Powered by 300.cn SEO

0311-89272359

0311-89272359

Message

Message

Message

Message