Key points of installation details of softened water equipment

- Categories:News

- Author:

- Origin:

- Time of issue:2022-01-12

- Views:0

(Summary description)The foundation needs to be level, and a floor drain or drainage ditch should be set up nearby to drain the recycled waste water. Separate power sockets should be provided near the equipment

Key points of installation details of softened water equipment

(Summary description)The foundation needs to be level, and a floor drain or drainage ditch should be set up nearby to drain the recycled waste water. Separate power sockets should be provided near the equipment

- Categories:News

- Author:

- Origin:

- Time of issue:2022-01-12

- Views:0

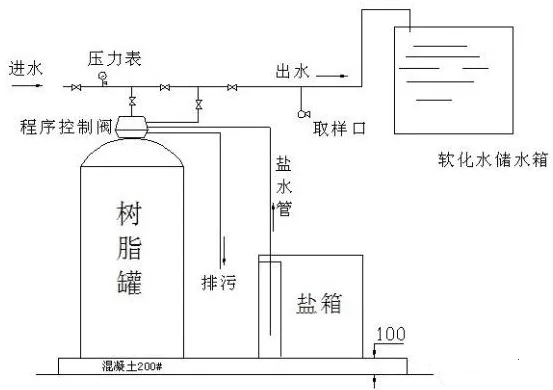

Installation requirements for softened water equipment

1. The foundation needs to be level, and a floor drain or drainage ditch should be set up nearby to drain the recycled waste water. Separate power sockets should be provided near the equipment

2. The salt tank should be close to the exchange tank, and the shorter the salt suction pipe, the better.

3. A y-type filter and a water meter should be installed on the water inlet pipe, and a sampling port should be provided at the water outlet.

4. Manual valves should be installed on the water inlet and outlet pipes, and a bypass valve should be installed between the water inlet and outlet, so as to continue to supply water during regeneration or maintenance.

5. If the water pressure of the water inlet is lower than 0.2MPa, an automatic booster pump should be added.

6. The salt in the salt box is required to be industrial salt, and iodized salt and calcium salt cannot be added. In order to ensure that the concentration of the salt solution in the salt tank can reach saturation, the dissolution time should be ensured not less than 6 hours, and the regeneration should be forced once before the first use.

7. When the raw water hardness is more than 6mmol/L, the selection of grades 1-2 should be increased.

8. The pipeline must be flushed before use to prevent impurities from clogging the valve body and contaminating the resin.

9. Antifreeze measures should be added to softened water equipment in northern winter.

Details of the installation of softened water equipment

First, choose the installation location of the softened water equipment

1. The system should be as close to the drain as possible.

2. If other water treatment facilities are needed, consideration should be given to reserving the installation location.

3. Because of the frequent addition of salt to the salt box, the location of the salt should be considered.

4. Do not install the softened water equipment within 3 meters from the boiler (the outlet of the softened water and the water inlet of the boiler), otherwise the hot water will flow back into the softened water equipment and damage the equipment.

Expose the device to a room temperature below 1°C and above 49°C. Keep away from acidic substances and sour gas environment.

Second: the connection of the softened water equipment pipeline

1. The connection of the pipeline system should comply with the "Water Supply and Drainage Pipeline Construction Standards.

2. Connect the inlet and outlet pipes according to the control diameter.

3. The inlet and outlet pipes should be equipped with manual valves, and a bypass valve should be installed between the outlet pipes. One is to facilitate the discharge of residues during the installation and welding process, so as not to pollute the resin; the other is to facilitate maintenance.

4. A sampling valve should be installed at the water outlet, and a Y-type filter is recommended for the water inlet pipe.

5. Try to shorten the length of the drain pipe (<6 meters), and do not install various types of valves. During the installation process, only PTFE tape can be used for sealing.

6. Space must be maintained between the drain pipe and the water surface of the drain to avoid siphoning.

7. Independent brackets must be set up between each pipeline, and it is not allowed to transmit the gravity and stress of the pipeline to the control valve.

Third: electrical connection of softened water equipment

1. All electrical connections must comply with electrical construction specifications.

2. Confirm that the electrical parameters of the controller are consistent with the power supply.

3. There is an independent power socket.

Fourth: Installation of water distributor and central pipe of softened water equipment

1. Use PVC glue to bond the central pipe and the water distributor base together.

2. Insert the bonded center tube into the resin tank.

3. Tighten the branch pipe of the water distributor on the water distributor base.

4. After the installation of the water distributor is completed, the central pipe should stand vertically in the center of the exchange tank, and then cut off the PVC pipe above the level of the tank mouth.

5. Put the resin tank in the selected position. Glue the center pipe and the lower water distributor firmly. Insert the center pipe into the resin tank with the lower water distributor facing down. The height of the center pipe and the lower water distributor should be flush with the tank mouth. Cut off the excess center tube. Note that the upper opening of the central tube should be smooth and free of burrs. Take out the center tube.

6. The resin is added to the resin tank and cannot be filled. The space left is the backwash space of the resin, and the height is about 40%-60% of the height of the resin layer.

7. Put the upper water distributor on the core pipe, or fix the upper water distributor on the bottom of the control valve first. Note that no matter where the upper water distributor is placed, it should be ensured that it will not fall and cause the resin to escape.

8. Insert the central tube into the bottom of the control valve. Note: The central tube must pass through the O-ring inside, and apply water-insoluble lubricant before screwing it into the valve to avoid damaging the sealing ring. Fix the upper water distributor on the multi-way valve.

Scan the QR code to read on your phone

-- Recommend --

Shijiazhuang Tianwang Environmental Protection Technology Co., Ltd.

Shijiazhuang Tianwang Environmental Protection Technology Co., Ltd. is a high-tech enterprise specializing in the research and development, manufacturing and sales of water treatment equipment.

Contact information

Production address: No. 9, Fengchan Road, Economic and Technological Development Zone, Shijiazhuang City

Office Address: 25th Floor, Block C, No. 310 Changjiang Avenue, Shijiazhuang High-tech Development Zone

Contact number:

Copyright ©2022 Shijiazhuang Tianwang Environmental Protection Technology Co., Ltd. 冀ICP备13019843号-1 Powered by 300.cn SEO

0311-89272359

0311-89272359

Message

Message

Message

Message